In modern farming, it is not up for debate that eggs must be kept clean and safe. If eggshells have dirt, feathers, or bacteria on them, they could make people sick and hurt your farm’s reputation. An egg washing machine is your secret weapon in this situation. In your mind, picture a dependable worker that cleans, sanitizes, and dries eggs faster than people can. This instrument makes work easier and lowers the risk of contamination, whether you run a small family farm or a huge business. Forget about cleaning eggs one at a time. These machines can handle hundreds or thousands of eggs an hour without damaging them. They are not only useful, but they are also necessary to meet food safety regulations and retain customers confident in your goods.

How Poultry Cleaning Equipment Works Step by Step

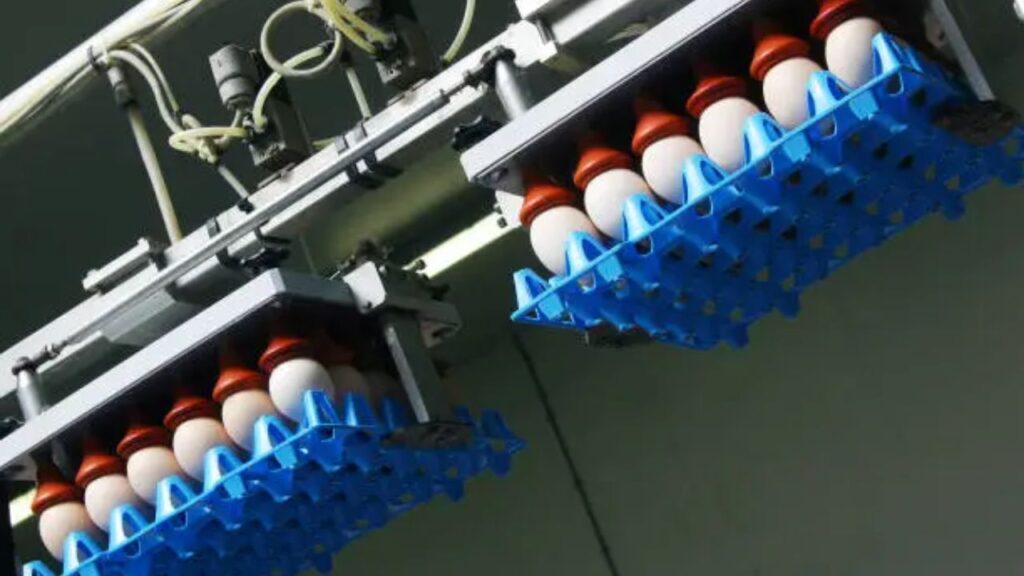

Ever wonder what happens inside an egg washing machine? It’s simpler than you think. First, eggs roll gently into the machine on soft conveyor brushes. Next, they’re sprayed with warm water (around 90–120°F)—hot enough to kill germs but cool enough to avoid “cooking” the egg inside. Specially designed food-safe detergent then foams away dirt without harming the shell’s natural protective layer. Rinse jets follow, spraying sanitizer like chlorine or ozone water to zap bacteria. Finally, soft air blowers dry eggs completely before they glide onto packing trays. The best part? Gentle rollers prevent cracks, while sensors adjust water flow for different egg sizes. No stress, no mess—just spotless eggs.

Top 5 Perks of Using a Farm Egg Washer

Investing in poultry cleaning equipment pays off fast. To begin with, it conserves much working time. Consider the fact that it would have been much easier to clean 2,000 eggs with the use of your hands as compared to 200. Second, it reduces waste. When you wash eggs by hand, they break 5–10% of the time. But when you wash them with machines, they break less than 1% of the time. Third, you can count on consistency. Every egg gets the same thorough clean—no skipped spots or human fatigue. Fourth, it boosts food safety compliance, making inspections less stressful. Fifth, it scales with your farm. Start with a small tabletop unit for 500 eggs/day or upgrade to industrial systems handling 20,000+. For busy farmers, time is money—and this tool gives you both back.

Picking Your Perfect Egg Cleaning System

Not all egg washing machines fit every farm. How many eggs do I pick up every day? Brush or spray washers that cost less than $1,000 are great for small enterprises that collect less than 1,000 eggs a day. For farms with 1,000 to 5,000 eggs, they need semi-automatic devices that can dry the eggs ($1,000–$5,000). Big companies need conveyor-fed monsters that clean with ozone and stack themselves ($5,000–$20,000). Also, think about space and power. There are those equipment that run on 110V outlets at home and others that require 220V lines in factories. Keep stainless steel frames that are hygienic to clean, rollers which can be set to varying size of eggs and the technical support at your location. Don’t overspend—but never compromise on food-grade materials.

Setting Up Your Egg Washer Machine Like a Pro

Placement is key for your farm egg washer. Install it near your collection area to avoid moving dirty eggs far. Use clean, soft water all the time since hard water leaves mineral stains. Connect drainage straight to the sewer system. Don’t use unclean water again. Pre-rinse eggs that are really dirty to keep the machine from getting clogged. Check the water temperature every day. If it’s too cold (below 85°F), germs can live. In case it is excessively hot (above 130o F), eggs might break. Only certified detergents should be used and not dish soap in order to retain the natural bloom to the egg. Check for cracks or residue in a test batch first. A good technique is to put a vinyl drape around the machine to keep splashes in and your work area dry.

Troubleshooting Your Poultry Cleaning Equipment

Even the best egg washing machine have problems sometimes. Eggs that are cloudy? It could be because the water that you are rinsing the water with is too cold. Raise it to 100°F. Is there a sticky residue? The concentration of the detergent could be low; be sure to measure it exactly. Eggs that are cracked? Make sure the rollers aren’t too tight or the eggs aren’t striking the sides too hard. Smells bad? Test the sanitizer levels with pH strips to see if they are low. The motor is whirring but nothing is happening. Switch off the conveyor and take away any blockage to it. Never unplug before you do any repairs! Keep on standby extra brushes and additional spray nozzles. Most problems can be fixed in a few minutes, and YouTube lessons are great for people who learn best by seeing.

Maintaining Your Egg Washer Machine for Long Life

If you take care of your egg cleaning system, it will last for decades. Flush all lines with clean water after each usage to keep the sprayers from getting clogged. Soak brushes in vinegar once a week to get rid of mineral buildup. Check the belts for wear and oil the rollers every month. Sanitizer filters should also be changed every three to six months. Store it somewhere that is dry to avoid rust. Stainless steel also has to be looked after. Off-season? When the temperature goes lower than the freezing point, make antifreeze flow into the water pipes. Include the maintenance dates in a wall calendar, such as, June 15, clean the drain pump. A machine that is carefully taken care of saves repair expenses in half and keeps eggs shiny.

Smart Savings: Budgeting for Poultry Cleaning Equipment

New egg washing machine range from $800 to $20,000. But think long-term: Hand-washing 5,000 eggs costs 25 labor hours weekly. At $15/hour, that’s $375/week. A $5,000 machine pays for itself in 3 months! Leasing is smart for tight budgets ($150–$500/month). Pre-owned models save 30–50%—just inspect for rust or motor issues. Look for ENERGY STAR-rated units to slash power/water bills. Factor in detergent ($20/month) and spare parts ($100/year). Grants like USDA REAP often cover 25% of farm equipment costs—apply early!

The Future of Egg Washer Machines

Egg cleaning systems are getting smarter. New AI models detect cracks via cameras and kick out flawed eggs automatically. Water-saving designs now recycle 90% of rinse water using UV filters. “Touchless” sanitizing with ultrasonic waves kills germs without chemicals—perfect for organic farms. Bluetooth apps alert your phone if water temps dip or brushes jam. Some even auto-order detergent when supplies run low! As robotics advance, expect fully automated “egg cleaning stations” that wash, grade, and pack without human hands. Sustainability is key too: solar-powered units are already hitting niche markets.

Machine vs. Hand vs. Store-Bought

| Feature | Hand Washing 🧼 | Store-Bought Solutions 🛒 | Egg Washing Machine 🥚⚡ |

| Food Safety | Risky – bacteria spreads in standing water | Varies – quality inconsistent | Guaranteed – controlled temps & sanitizers kill germs |

| Egg Breakage | High (5-10% cracked) | Already packaged (N/A) | Under 1% – gentle rollers protect shells |

| Labor Time | 200 eggs/hour (back-breaking!) | No farm labor | 2,000+ eggs/hour (10x faster!) |

| Consistency | Uneven – misses spots | Depends on brand | Perfect every time – automated process |

| Water/Sanitizer Use | Wasted – changes needed constantly | N/A | Precise control – no waste, meets FDA rules |

| Cost Over Time | $375/week for labor (5k eggs) | Recurring supply costs | Pays for itself in <3 months – slashes labor |

| Scalability | Impossible for large farms | Limited by supplier | Grows with you – small to industrial models |

| Human Touch | Backaches, wet sleeves | Zero control | Pride in product – spotless eggs = happy customers |

Conclusion

It is not a luxury to have an egg washing machine; rather, it is your first line of defense against waste, sickness, and inefficiency. In marketplaces, dirty eggs are sold for a price that is thirty percent lower. A single recall has the potential to put a small farm out of business. Using this gadget, you will be able to concentrate on feeding the hens rather than cleaning the shells. It is a statement that is directed toward the clients, saying, “We care about your safety.” Start out small if that’s what’s required, but get started. Clean eggs are the foundation of trust. In order to increase sales, trust is essential. And that is how the growth of small farms occurs.

Why Egg Cleaning Equipment Matters

The requirements regarding food safety are tighter than ever these days. The eggs that have salmonella and other pathogens on the egg shells should be cleaned. Proper cleaning of egg shells is not an act of kindness, it is the law. The egg washer machine does not merely remove the dirt but also a material accurate at the water temperature and food-grade sanitizers to eliminate the invisible germs cannot be removed. Small farmers may even say, Our house is always hand washed. However, when the water is not changed after some time or the cleaning is not frequent, then germs may be transmitted. Safety is handled by machines ensuring that the pH, temperature, and sanitizer content of the water kills the germs without damaging the eggs. And it is not about shortcuts, but about making sure your family and your business are not subject to costly lawsuits or a recall.

FAQs

1. Can I wash eggs without a machine?

Yes but it’s slow and deadly. So washing your hands as part of a regular activity makes little sense – and besides leaking water either comes from the same surface you wash on, or goes elsewhere while you get moist.

2. Do egg washers damage the eggshell?

Not if you take care of it. Using gentle brushes and controlled water pressure is better for shells than cleaning them by hand.

3. How many eggs can a small machine clean hourly?

Tabletop devices can process between 300 and 500 eggs per hour. Industrial models can clean more than 10,000.

4. What sanitizers are safe for egg washing?

Every option approved by FDA consists of chlorine (50100 ppm), ozone or hydrogen peroxide. Never, never bleach!

5. Can I wash eggs right after laying?

Give it 4 to 6 hours. Fresh eggs have a covering that protects them and plugs the pores. This barrier gets weaker if you wash it too soon.